“If you don’t have it, you can’t sell it.”

Featured on CED Mag.

That’s Carlos Teran’s staunch belief, and it’s the business philosophy that has fueled the success of Teran Industries Inc.

Teran is founder and head of the Miami-based company that manufactures and distributes a wide range of attachments for heavy machinery, including buckets, rippers, hydraulic hammers and more, all with Teran’s name on them. And everything is in stock, whether it’s at the Miami headquarters or Teran’s Midwest Distribution Center in Peru, Illinois.

That’s what Teran believes sets his company apart, and it’s a business model he takes pride in.

“Probably 95 percent of what we sell is in stock,” Teran said. “Very rarely am I out of stock, because we keep an average of 2,500 attachments in stock across both locations.”

“The goal for me is to have everything the customer needs, and we have one of the largest inventories in the country. Many other companies require weeks to manufacture a product, and we try to keep most of them in stock. If you don’t have it, you can’t sell it,” he said.

Teran Industries offers a full line of attachments: buckets, rippers, hydraulic hammers, quick couplers, thumbs, rakes, grapples, gensets, bucket pins, U/C components and long-reach arms. The company’s bread-and-butter item is heavy-duty, general-purpose buckets.

Most of Teran Industries’ products are manufactured exclusively for Teran in China, and the current tariffs are a concern, Teran said.

“Think of about 200 containers in imports; 25 percent of that is a lot. And not necessarily are you able to sell at a higher price, so it’s affecting my margins a little bit. Still, the turnover continues to be increasing year after year – we’re seeing double-digit growth over the past few years, due to the availability of products and more customer awareness.”

That customer awareness is worth its weight in gold to Teran. It’s something else the company strives for, and one of the reasons it became a member of Associated Equipment Distributors.

“We’re going to exhibit at the next AED Summit and take more advantage of the opportunities that the Association offers,” he said. “What you have at AED, you don’t have at all the other conventions: at Summit, you have the owners of the companies, and you can strike a deal right there.”

Teran gets his name out where it needs to be without a cadre of salespeople, which is an innovative way to do business, he said.

“What I do instead of having salespeople throughout the country is we advertise heavily and we participate in auctions throughout the United States and Canada,” he said. “We frequently do auctions with the biggest heavy equipment auctioneers in the country, and people see the great quality of our products, so they come back for more.” It’s not to get rid of surplus equipment – not at all – rather, it’s a way of getting his product into new hands, thus gaining new customers.

Aside from having so much inventory invested, Teran’s top challenge is no different than most companies: finding good people.

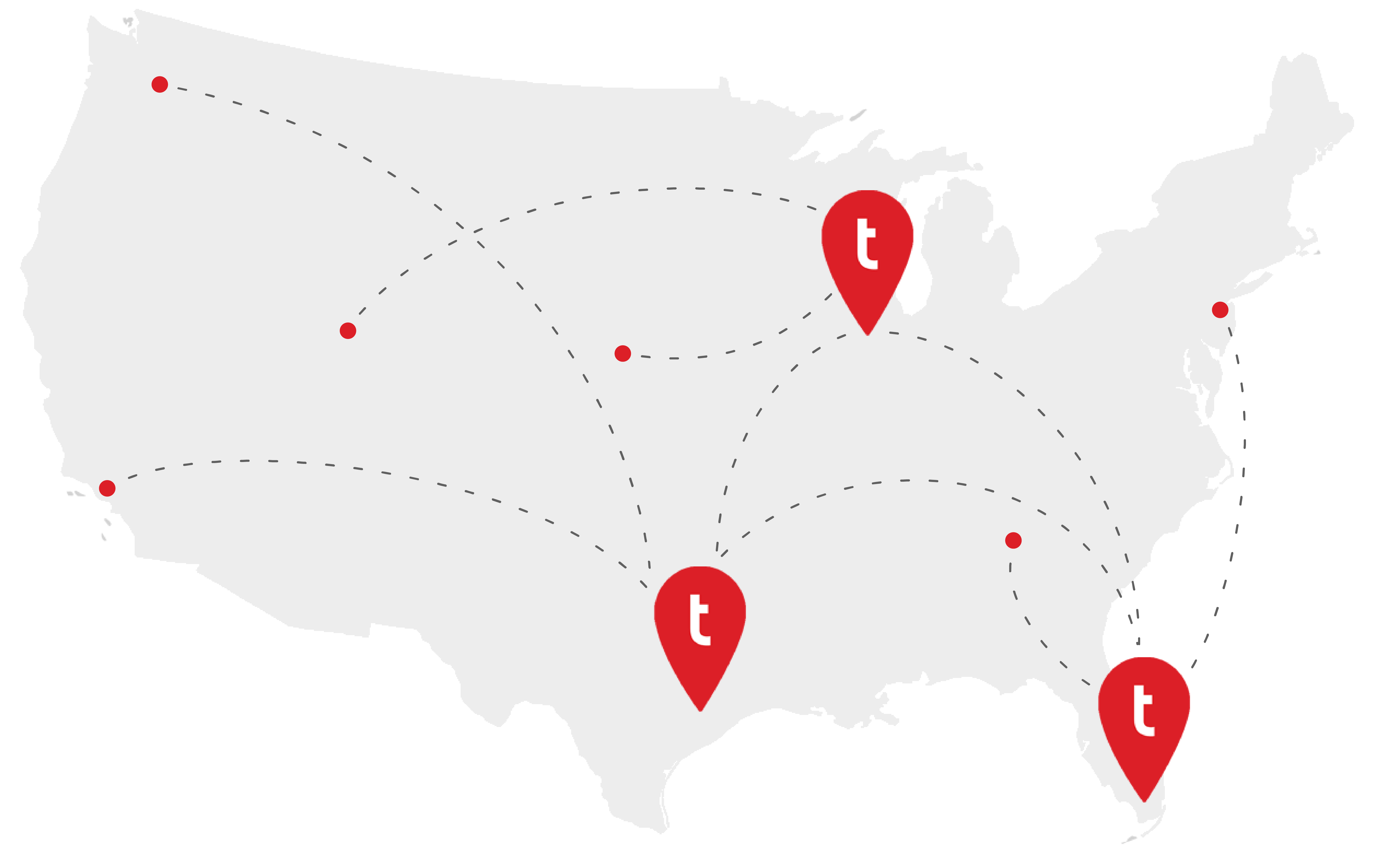

“People are number one. It is a very specialized industry, and you need someone you can trust,” Teran said. “I have the best people today, and I’m very open in the way that I work with my people. When we get more people, I will open three or four more locations: one in Texas, one in California, one in Colorado, maybe one in the Northeast. Then we could cover everything with one-day transit time, where now we average two to three days. In the Midwest, it’s next day, but if I have a product in Illinois and it’s going to the West Coast, it will take three to four days.”

Ultimately, Teran would like to have six locations nationwide. He thinks it can happen. “I’d like to do it for yesterday,” Teran said, laughing. “Time goes by a lot faster than what we want.”